Choosing the right paver block making machine in India is crucial for businesses looking to enter or expand in the construction and paving industry. With the growing demand for interlocking tiles making machine in India and paver blocks, investing in a high-quality machine can significantly boost your productivity and profitability. This guide will help you navigate the process of selecting the ideal paver block making machine for your needs.

Understanding the Basics of Paver Block Making Machines

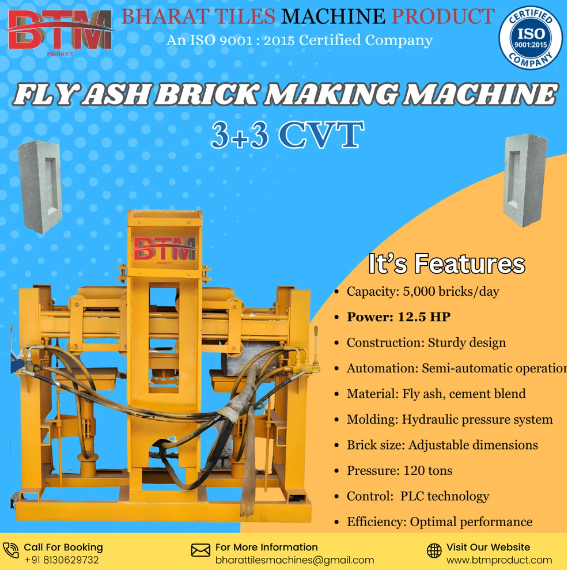

Before diving into the selection process, it’s essential to understand what paver block making machines are and how they work. These machines are designed to produce various types of concrete blocks, including interlocking tiles making machine in India, paver blocks, and in some cases, fly ash brick making machine in India. They use a combination of vibration and compression to mold concrete or other materials into the desired shape and size.

Types of Paver Block Making Machines

1. Stationary Machines

Stationary paver block making machines are ideal for large-scale production facilities. They offer high output and are suitable for businesses with a dedicated production area.

2. Mobile Machines

Mobile or portable paver block making machines are perfect for on-site production or businesses that need flexibility in their operations. They can be easily transported to different locations as needed.

3. Automatic Machines

Automatic paver block making machines require minimal human intervention and are best for high-volume production. They often come with advanced features like automatic feeding and stacking systems.

4. Semi-Automatic Machines

Semi-automatic machines strike a balance between manual control and automation. They are suitable for medium-scale production and offer a good mix of efficiency and affordability.

Key Factors to Consider When Choosing a Paver Block Making Machine

1. Production Capacity

Consider your current and future production needs. BTM Product offers a range of machines with varying capacities to suit different business scales.

2. Types of Blocks Produced

Ensure the machine can produce the types of blocks you plan to offer. Some machines are versatile and can produce both interlocking tiles making machine in India and paver blocks, while others may specialize in specific types.

3. Quality of Output

The quality of the finished product is crucial. Look for machines that produce consistent, high-quality blocks with proper density and strength.

4. Energy Efficiency

Energy-efficient machines can significantly reduce your operating costs in the long run. Check the power consumption and efficiency ratings of different models.

5. Ease of Operation and Maintenance

User-friendly machines with simple controls and easy maintenance requirements can improve productivity and reduce downtime.

6. Durability and Build Quality

Invest in a machine built with high-quality materials to ensure longevity and reliability. BTM Product is known for its durable and robust machines.

7. Customization Options

Some manufacturers offer customization options to tailor the machine to your specific needs. This can be particularly useful if you have unique production requirements.

8. After-sales support and Spare Parts Availability

Choose a manufacturer that offers reliable after-sales support and easy access to spare parts. This can minimize downtime in case of any issues.

Assessing Your Business Needs

Before making a decision, carefully assess your business needs:

1. Production Volume

Estimate your daily or monthly production requirements to choose a machine with the appropriate capacity.

2. Available Space

Consider the space available in your production facility to ensure the machine fits comfortably and allows for efficient workflow.

3. Budget

Determine your budget, keeping in mind that investing in a high-quality machine can lead to better returns in the long run.

4. Workforce Skill Level

Consider the skill level of your workforce when choosing between automatic and semi-automatic machines.

5. Future Growth Plans

Think about your future expansion plans and choose a machine that can accommodate potential growth in production.

Comparing Different Brands and Models

When comparing different brands and models of paver block making machine in India, consider the following:

1. Technical Specifications

Compare the technical specifications of different machines, including production capacity, power consumption, and dimensions.

2. Customer Reviews and Testimonials

Look for customer reviews and testimonials to get real-world insights into the performance and reliability of different machines.

3. Brand Reputation

Choose reputable brands like BTM Product that have a proven track record in the industry.

4. Warranty and Support

Check the warranty terms and after-sales support offered by different manufacturers.

5. Price-to-Performance Ratio

Compare the features and capabilities of different machines relative to their price to ensure you’re getting the best value for your investment.

The Importance of Proper Installation and Training

Once you’ve chosen your paver block making machine, proper installation and training are crucial for optimal performance:

1. Professional Installation

Ensure the machine is installed correctly by professionals to avoid issues and maximize efficiency.

2. Operator Training

Invest in comprehensive training for your operators to ensure they can use the machine effectively and safely.

3. Regular Maintenance Schedule

Implement a regular maintenance schedule to keep your machine in top condition and prevent unexpected breakdowns.

Expanding Your Product Line

Consider machines that offer versatility in production. For example, some paver block making machine in India can also produce fly ash brick making machine in India, allowing you to diversify your product offerings. BTM Product offers machines capable of producing both paver blocks and fly ash bricks, providing flexibility for your business.

Conclusion

Choosing the right paver block making machine in India is a crucial decision that can significantly impact your business’s success. By carefully considering factors such as production capacity, quality, energy efficiency, and after-sales support, you can make an informed choice that aligns with your business needs and goals.

Remember to thoroughly research different brands and models, including those offered by reputable manufacturers like BTM Product. Take the time to assess your current and future needs, and don’t hesitate to seek expert advice if needed.

Investing in a high-quality interlocking tiles making machine in India or a versatile paver block making machine can set your business up for long-term success in the competitive construction and paving industry. With the right machine and proper maintenance, you’ll be well-equipped to meet the growing demand for paver blocks and interlocking tiles in the Indian market.